Effecta washing compartment

- optimized liquor level

- nip washing

- tensionless and crease-free fabric transport

- tight strand passage

- minimized use of operation agents

- reproducibility of finishing results

- short amortisation time

- easy to operate

- indirect steam through thermplates

- external isolation

- quick heating of the liquor through the large surface

- even temperature distribution over the full width

- reduced liquor volume

- gentle but intensive removal of impurities from fabric surface and out of the fibre core

- increase of liquor exchange

- bath separation

- simplification of the subsequent processes due to efficient precleaning

- suction from both sides

- removal of fluffing from both sides

- bath separation

- liquor pick up from 90 to 130 %

- excellent liquor exchange and penetration to the core of the fibre

- no surface reaction or cloudiness in the steamer

- no titration necessary because of fast bath exchange

- minimized fibre damage

- chemicals can be dosed separately

- dosing dependent on water flow (ml/kg)

- water supply via level

- easy operation via PC

- first filling recipe controlled

- online calculation of add on and exchange factor

- automatic adaption of concentration in case of recipe and fabric exchange

- consumption data registration

- complete absorption of the bleaching liquor

- evenness of liquor application

- avoidance of dripping and creation of stripes

- counter-current fabric/liquor

- formation of liquor nips at the deflection point (penetration of the liquor into the fabric)

- efficient heating of the fabric

- steam-sealed passage avoids pollution of the atmosphere

- no cooling of the fabric, no condensation of the dissolved impurities

- stress free opening and centering of the fabric by swivelling centering device

- guaranteed crease-free fabric entrance in the final washing

- pH-probe for real value registration

- set value adjustable via machine control

- liquor circulation pump

- dosing pump for acid with injection device

- recipe controlled fabric filling and dwelling time

- careful fabric take-off from the upper part of the fabric package

- exact fabric take-off by sensor rollers

- overfilling-safety device for the rollerbed

- program controlled change from plaited to tight strand

- ideal steam condition and temperature distribution through sump heating

Vertical steamer

- dwelling zone in tight-strand fabric guiding, therefore avoidance of formation of creases and cross

- marks during plaiting

- heated steamer roof

- short loop plaiter for exact fabric package formation

- lowest fabric tension by frequency regulated additional drives of the upper guide rollers

- fabric breakage surveillance

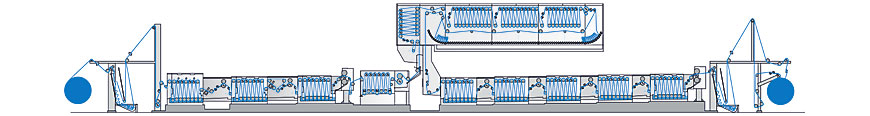

Complexa Scouring and bleaching range |

|

![]() Please click here for more information

Please click here for more information