Thermoflush

- increase of washing capacity

- quick energy transfer

- dissolving of surface impurities

- core diffusion

- extremely silent suction device for the following processes:

- pre-treatment

- preparation washing

- dye and print washing

- intermediate suction

- suction after immersion treatment

- suction from both sides

- optimized liquor level

- nip washing

- tensionless and crease-free fabric transport

- tight strand passage

- minimized use of operation agents

- reproducibility of finishing results

- short amortisation time

- easy to operate

- indirect steam through thermplates

- external isolation

- quick heating of the liquor through the large surface

- even temperature distribution over the full width

- reduced liquor volume

- soaping processes for washing after dyeing and printing, relaxation, dwelling processes, spinning oil washing, short time bleaching

- other time related processes

- no change of the fabric threading

- therefore high productivity

- after each diffusion drum new formation of package

- pH-probe for real value registration

- set value adjustable via machine control

- liquor circulation pump

- dosing pump for acid with injection device

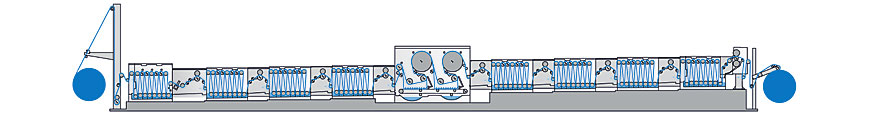

Effecta-Unirelaxa Washing after printing and dyeing |

|

![]() Please click here for more information

Please click here for more information